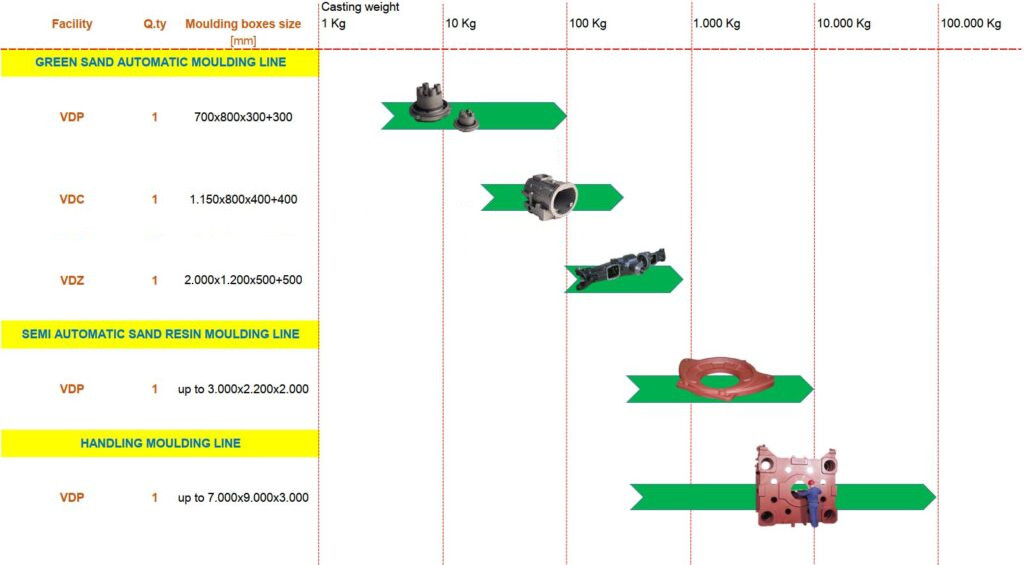

The production plants in the VDP group

VDP

1 green sand automatic moulding plant BMD for flasks up to 700x800x(300+300) mm and weights up to 100 kg. / 1 sand-resin semi-automatic moulding plant IMF for flasks up to 3.000×2.200×2.000 mm and weights up to 10.000 kg. / 1 sand-resin manual moulding plant for flasks up to 7.000×9.000×3.000 mm and weights up to 100.000 kg.

VDC

1 green sand automatic moulding plant HWS for flasks up to 1.150x800x(400+400) mm and weights up to 400kg.

VDZ

1 green sand automatic moulding plant HWS for flasks up to 750/750x (350+350) mm and weights up to 100 kg. / 1 green sand automatic moulding plant SAVELLI for flasks up to 2.000×1.200x(500+500) mm and weights up to 800 kg.

Green sand moulding plant

The green sand moulding plant is structured for flasks of dimensions of 800×700 H tot. 600 (300+300)mm. The sand supply system, alongside the automatic moving system, guarantee an average production of 120 moulding boxes per hour, with minimum order quantity of 25 boxes. The range of the weights of castings produced goes from 1 kg to 150 kg.

Hand moulding plant

The hand moulding plant is the heart of large-sized casting production whit specialised personnel that works in 3 shifts. The sand mixers (with filling flow of 20 and 60 tons per hour) and many steel moulding boxes from 1.300 x 1.300 mm, to 9.000 x 12.000 mm, allow castings production up to 100 tons gross. The pouring process, made with ladles, has safely performed into 7 pits with depth ranging from 2 to 4 meters.